Köngen – The backbone of the German economy cannot react quickly enough to weak economic phases or game changers. Around half of mechanical engineering companies are slowed down by static processes, business consultancy Staufen found in a study. In view of a declining order intake, savings potential should now be leveraged and efficiency increases implemented.

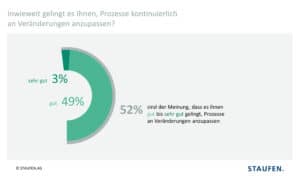

“The German Mechanical Engineering Industry Association is forecasting a further decline in production for the current year after a decline was already reported in 2019,” warns Wilhelm Goschy, Board Member of business consultancy Staufen AG. The economic downturn had a particularly drastic effect on the companies concerned, since only 52 percent of German mechanical engineers were in a good position to continuously adapt their processes to changes. These are the results of the “Success in Change” study from business consultancy Staufen. More than 400 top executives from German companies were interviewed, including around 100 from the mechanical engineering industry.

The transformation expert therefore advises to optimize internal processes in order to cushion the weak order intake: “From years of experience in practical projects and market analyses, we know that many companies can achieve savings of up to 30 percent. The focus should not only be on production but also on indirect and upstream or downstream areas.”

The possibilities of digitization and automation have so far been used in production in mechanical engineering. Robots can be found working in every larger assembly hall as flexible load cranes or laser welders with millimeter precision. According to Goschy, the possible uses of automation can also be extended to areas in the back office or sales of manufacturing industrial companies with the help of digitization. Robotic Process Automation (RPA) in particular offers enormous savings potential. Many routine tasks that tie up enormous resources in normal day-to-day business can also be handled easily by software robots. The efficiency advantages achieved could compensate for the drop in orders and at the same time free up capacities that can be used for preparatory measures for the next upswing.

Save the date: NEXCON Lead Conference on March 5, 2020

NEXCON is an international, fully virtual congress for qualification, knowledge exchange and process improvement in the field of smart manufacturing. In 2020, four one-day conferences with different focuses will take place on the platform. In addition, NEXCON offers seminars, coaching and expert discussions all year round. Our goal is to break down financial and location-related barriers and enable easy access to knowledge, global cooperation and smart manufacturing exchange. Additional information on participants, exhibitors and partners can be found at: www.nexcon.digital

About the study “Success in Change”

Business consultancy Staufen surveyed a total of 421 companies in Germany on the subject of “Success in Change” for the “Change Readiness Index 2019.” More than 65 percent of the companies surveyed come from the mechanical and plant engineering industry, the electrical industry and the automotive industry. The study can be downloaded at: https://www.staufen.ag/studien

|

More Information: STAUFEN.AG Tel: +49 7024 8056 152 |

Press: Thöring & Stuhr Tel: +49 40 207 6969 83 |

About Staufen AG – www.staufen.ag

Inside every company there is an even better one. With this conviction, Staufen AG has been advising and qualifying companies and employees for more than 25 years. Markets are on the move – the competitive pressure is enormous. Staufen helps to quickly bring about the right changes, increase productivity, improve quality and increase innovative strength. With the most fitting strategies and methods, international transformation consulting ensures rapid and measurable success. With an aim towards raising the potential available in every company, Staufen consultants work side-by-side with company executives and employees to establish a vibrant and long-term culture of change. Staufen subsidiary Staufen Digital Neonex supports medium-sized industrial companies on their path to digital transformation. The Academy of Staufen AG also offers certified, practice-oriented training courses. From the international locations, more than 340 employees serve customers all over the world. In 2019, Staufen AG was recognized by “brand eins Wissen” as “Best Consultants” for the sixth year in a row. According to the renowned industry study “Hidden Champions 2020,” the consulting firm is Germany’s best lean management consultancy and was honored several times with the “Best of Consulting” award by the “Wirtschaftswoche” journal.