Three quarters of German industrial companies are not convinced about predictive maintenance. Their performance capability is not sufficient or, at least still upgradeable. Only 6 percent currently see applying predictive maintenance on the basis of process and machine data as being highly beneficial. These are the results of what is now the fourth German Industry 4.0 Index. Approximately 400 German industrial companies were surveyed on behalf of Staufen Consultancy.

Surprisingly, one of the oft-quoted classic examples of an Industry 4.0 solution that is already being used in real-world applications is receiving little support. Surprising because two thirds of companies indicate that they are already applying the principle in-house or are offering it as a service. In addition, 20 percent of respondents did not venture to provide an assessment, a remarkably high number.

Thomas Rohrbach, Managing Director of Staufen Digital Neonex GmbH, does not see this as remarkable: “All too often, concepts from the digital transformation toolbox are simply used as catchwords for long-held ideas. The transition from simple remote maintenance and condition monitoring to predictive maintenance is a smooth one. But not until users truly experience added value will the principle convince companies of its long-lasting success.”

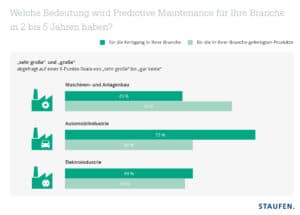

In general, the benefits of predictive maintenance are overestimated. “A vast majority of machine break-downs are due to factors that cannot be solved by predictive maintenance; the biggest cause is operator error,” says digitalization expert Rohrbach. “Predictive maintenance can achieve true added value if it is used in conjunction with other activities, such as intelligent monitoring of process data to optimize processes and materials, or digital assistant systems, which prevent human errors.” Only then can industry’s high expectations of predictive maintenance be met; half the respondents acknowledged that in the coming two to five years, predictive maintenance will play a key role.

Mark this date in your calendar: Nexcon, March 2, 2018

Nexcon is the first German-language digital convention covering the topic of Industry 4.0. The focus of presentations and virtual exhibits is the smart factory. You can participate from any location that has internet access. The digital convention starts at 9 a.m. and ends at about 6 p.m. Access is free for participants. Participants, exhibitors and content partners can obtain more information at www.nexcon.digital

German Industry 4.0 Index 2017

For the German Industry 4.0 Index 2017, Staufen AG, together with Staufen Digital Neonex GmbH, surveyed a total of 394 German companies. More than 70 percent of the companies surveyed were from the mechanical and plant engineering, automotive and electronics industry.